Birta lagu farsameeyay CZU

Waa maxay hababka wax soo saarka eeBirta Qaybta Qabow Samaysan?

Habka wax soo saarka ee mashiinnada xariijimaha qabow-duuban waxay inta badan koontaroolaan diyaarinta billet, qajaarka, duubista qabowga, nuugista iyo dhamaystirka.

Diyaarinta madhan waxay u baahan tahay halbeeg kiimiko ah, ballac iyo miisaan dhumucdiisuna tahay (farqiga saddex-dhibcood iyo faraqa xariiqda isku midka ah), iyo qallooca sickle waa inuu buuxiyaa shuruudaha, oogada sare waa inay ahaataa mid siman oo ka madax bannaan dildilaaca, laalaabka, delamination, daloolada, aan- ka mid noqoshada macdan, iwm.

Birta jeexjeexan waa in la toosiyaa oo dabada la laysiyaa ka hor inta aan la qaadin qajaar xidhiidhsan.Ujeedada ugu weyn ee pickling waa in laga takhaluso miisaanka birta oksaydhka.Inta lagu jiro habka qajaarka, xoojinta iyo heerkulka xalka asiidhka iyo waxa ku jira milixda birta ah ee xalka asiidhka waa in la xakameeyaa.

Si loo xakameeyo dhumucda iyo qaabka saxanka, dhimista, xawaaraha, xiisadda iyo qaabka duubista waa in la hagaajiyaa.Dhumucdiisuna waxaa inta badan gacanta ku AGC, iyo qaabka saxan inta badan waxaa gacanta ku by hagaajinta profile duudduuban (roll taaj iyo habka magdhow taaj), sida HC, CVC, iwm.

Annealing waxa loo qaybiyaa badhista dhexe iyo dhammaystiraynta.Xakamaynta xaruntu waa in la baabi'iyo adkeynta shaqada, iyo nuugista alaabtu waa in la helo qaabka iyo shaqada loo baahan yahay.Foornooyinka dabcinaya waxaa ka mid ah foornooyinka wax baabi'iya oo isdaba jooga iyo foornooyinka wax baabi'iya nooca gambaleelka.Habka nuugista foornada nuujinta nooca gambaleelka waa in ay xakamayso saamiga gaaska ilaalinta ee foornada, wakhtiga kuleylka, iyo wakhtiga qaboojinta;habka nuugista foornada foornada ee isdaba-joogga ah waa in ay xakamayso heerkulka, xawaaraha, wakhtiga iyo jawiga iyada oo loo eegayo qalooca annealing.Xakamee xiisadda xariijimaha foornada si aad u hubiso qaabka saxanka, oo xakamee taajka duubka foornada si aad uga fogaato leexashada.

Dhamaystirka waxaa ka mid ah fiditaanka, goynta, saliidaynta iyo baakadaha.Flatness waxay hagaajin kartaa qaabka saxanka, nadiifi dusha sare oo aad hesho hawlaha loo baahan yahay.Habka habayntu waa in uu xakameeyaa dhererka falinka, xiiridduna waa in ay inta badan xakamaysaa miisaanka iyo tayada dusha sare, saliidduna waa in ay noqotaa mid isku mid ah, baakadduna waa in ay buuxisaa shuruudaha la cayimay, taas oo ku habboon kaydinta, gaadiidka iyo bixinta.

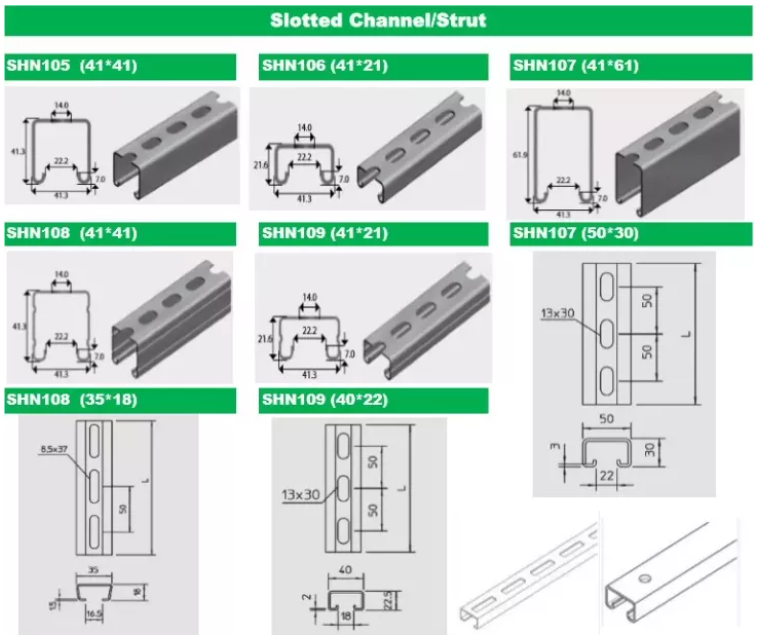

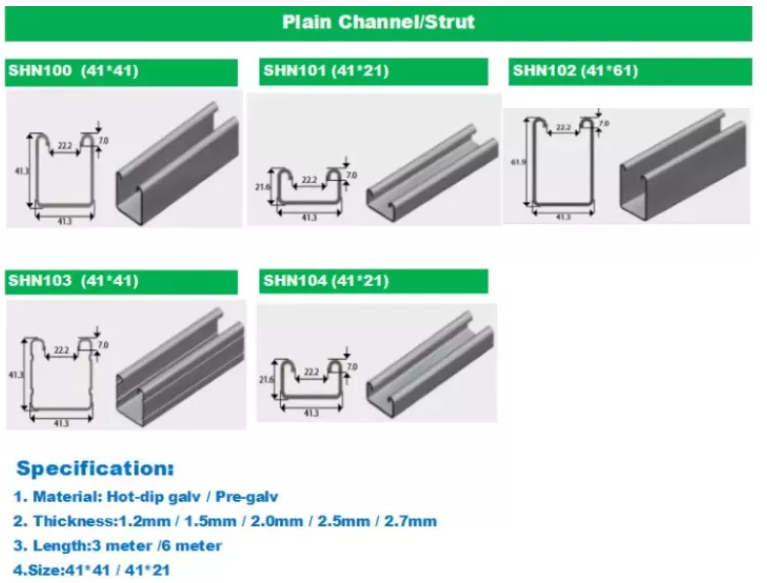

| MAYA | Cabbirka | Dhumucda | Nooca | Dusha sare Daawaynta | ||

| mm | Inji | Dhumucda | Qiyaas | |||

| A | 21*10 | 13/16*13/32" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | La jeexjeexay, Adag | HDG,PG, PC |

| B | 21*21 | 13/16*13/16" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | La jeexjeexay, Adag | HDG,PG, PC |

| C | 41*21 | 1-5/8*13/16" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | La jeexjeexay, Adag | HDG,PG, PC |

| D | 41*22 | 1-5/8*7/8" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | La jeexjeexay, Adag | HDG,PG, PC |

| E | 41*25 | 1-5/8*1" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | La jeexjeexay, Adag | HDG,PG, PC |

| F | 41*41 | 1-5/8*1-5/8" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | La jeexjeexay, Adag | HDG,PG, PC |

| G | 41*62 | 1-5/8*27/16" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | La jeexjeexay, Adag | HDG,PG, PC |

| H | 41*82 | 1-5/8*3-1/4" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | La jeexjeexay, Adag | HDG,PG, PC |

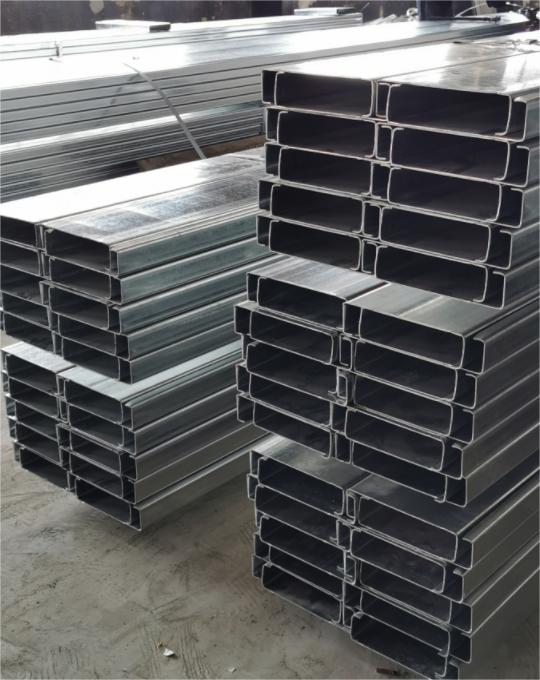

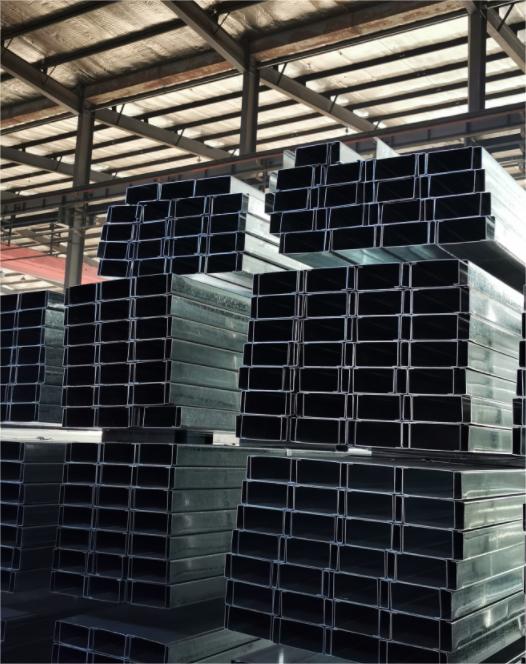

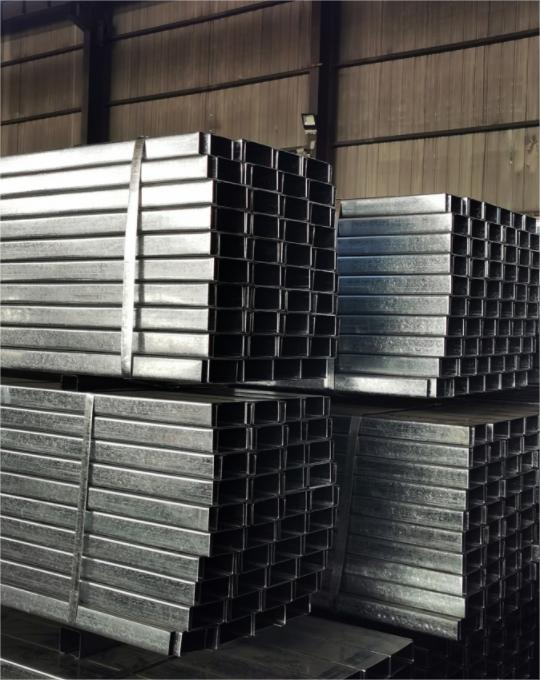

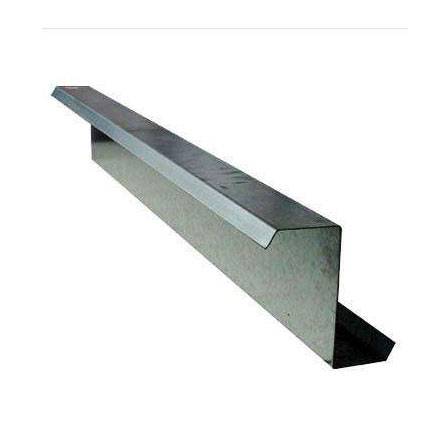

Dhammaanqabow sameeyay birta c profilewaxaa loo qaabeeyey by processing si toos ah by C-birta ka-up mishiinka, taas oo marka loo eego cabbirada C-birta la siiyey, si toos ah u dhamaystiri kartaa habka samaynta C-steel ee.

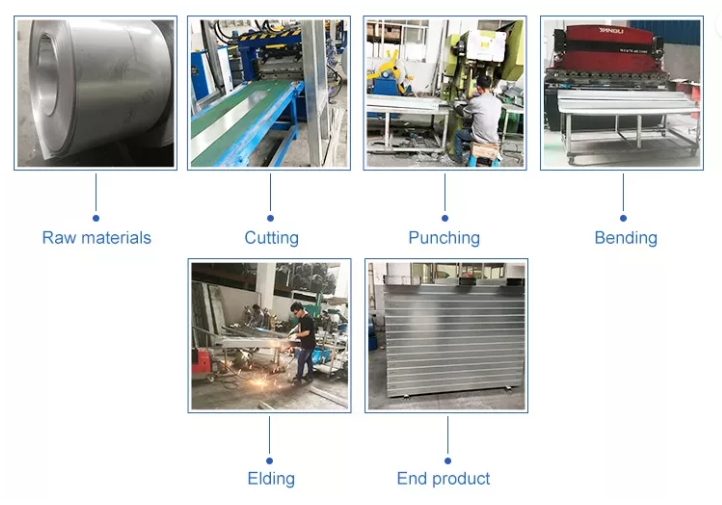

Quudinta-Balaadhinta- Samaynta-Qiyaamaynta-Isku toosinta-Cabirka Dhererka-Furitaanka Daloolka Wareega ee Tie-bar-Funching Oval Connection Hole-Qalabaynta Goynta